Use Method of Self-priming Water Pump

Preparations and inspection before starting

1. This series of self-priming pumps are lubricated with high-quality calcium-based butter and No. 10 engine oil respectively according to the working condition of the pumps. If the pump is lubricated with butter, butter should be injected into the bearing box regularly. If the oil level is insufficient, the pump should be supplemented.

2. Check whether the liquid storage in the pump shell is higher than the upper edge of the impeller. If it is insufficient, the liquid storage can be injected directly into the pump body from the filling port on the pump shell. It should not start operation under the condition of insufficient liquid storage. Otherwise, the pump can not work normally and is liable to damage the mechanical seal.

3. Check whether the rotating parts of the pump have a card knock phenomenon.

4. Check the bottom of the pump body and the nuts at each joint for loosening.

5. Check the coaxiality and parallelism of pump shaft and motor spindle.

6. Check whether the inlet pipeline is leaking or not. If there is leaking, we must try to eliminate it.

7. Open the valve of the suction line and slightly (not fully) open the outlet control valve.

1. This series of self-priming pumps are lubricated with high-quality calcium-based butter and No. 10 engine oil respectively according to the working condition of the pumps. If the pump is lubricated with butter, butter should be injected into the bearing box regularly. If the oil level is insufficient, the pump should be supplemented.

2. Check whether the liquid storage in the pump shell is higher than the upper edge of the impeller. If it is insufficient, the liquid storage can be injected directly into the pump body from the filling port on the pump shell. It should not start operation under the condition of insufficient liquid storage. Otherwise, the pump can not work normally and is liable to damage the mechanical seal.

3. Check whether the rotating parts of the pump have a card knock phenomenon.

4. Check the bottom of the pump body and the nuts at each joint for loosening.

5. Check the coaxiality and parallelism of pump shaft and motor spindle.

6. Check whether the inlet pipeline is leaking or not. If there is leaking, we must try to eliminate it.

7. Open the valve of the suction line and slightly (not fully) open the outlet control valve.

8. Pay attention to check whether there is leakage in the pipeline system.

Application Method of Self-priming Water Pump

Pump shutdown:

1. First of all, the gate valve in the spitting pipeline must be closed. 2. Stop the pump from turning. 3. In the cold season, the liquid storage in the pump body and the water in the cooling chamber of the bearing body should be emptied to prevent frost cracking of the machine parts.

Maintenance of Self-priming Pump

The pump is characterized by simple and reliable structure and durability. Normally, the pump does not need to be disassembled and maintained frequently. When the fault is found, it can be removed at any time.

1. When maintaining the self-priming pump, attention should be paid to several main parts.

A. Rolling bearing: When the bearing wears to a certain extent after long-term operation of the pump, it must be replaced.

B. Front and rear sealing rings: When the sealing rings wear to a certain extent, they must be replaced.

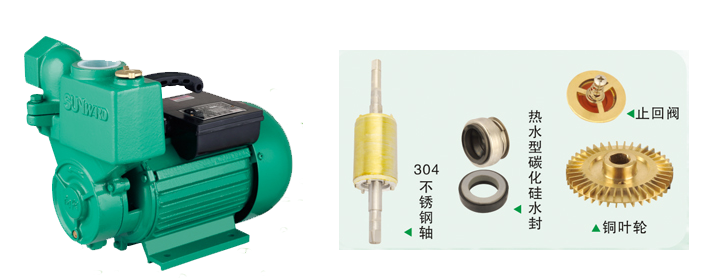

C. Mechanical seals: Mechanical seals should not be disassembled and inspected without leakage. If serious leakage occurs at the lower end of the bearing body, the mechanical seal shall be disassembled and inspected. When assembling and disassembling mechanical seals, it is necessary to take them lightly, pay attention to the cleaning of the mating surface, protect the mirror of the static ring and the moving ring, and strictly prohibit knocking and collision. The main reason for leakage due to mechanical seal is mirror roughening of friction pair. The repairing method can grind the end face of the friction pair to restore the mirror surface. Another reason for leakage of mechanical seals is improper installation of "0" rubber seals (or cushions) or deformation and aging. At this time, it is necessary to adjust or replace the "0" seal ring for reassembly.

2. Pump disassembly sequence:

A. Remove the motor or the coupling.

B. Remove the bearing assembly, check the radial clearance between the impeller and the front orifice ring, check whether the impeller nut is loose or not.

C. Fold down the impeller nut, pull out the impeller, check the radial clearance between the impeller and the back sealing ring.

D. Loosen the fastening screw of the mechanical seal, pull out the moving ring part of the mechanical seal, check the fit of the end faces of the dynamic and static rings, and check the sealing condition of the "0" seal ring (or cushion).

E. Roll out the firm nut of the coupling and pull out the coupling.

F. Remove the end cap of the bearing and the bearing of the pump shaft.

G. Assemble in reverse order during installation.